Aoki Blow Molding Machine, New in 2020

Item No. 5885

Year 2020

Aoki Blow Molding Machine, New in 2020

Item No. 5884

Year 2020

Aoki Blow Molding Machine, New in 2020

Item No. 5883

Year 2020

Aoki Blow Molding Machine, New in 2020

Item No. 5877

Year 2020

Aoki Blow Molding Machine, New in 2020

Item No. 5876

Year 2020

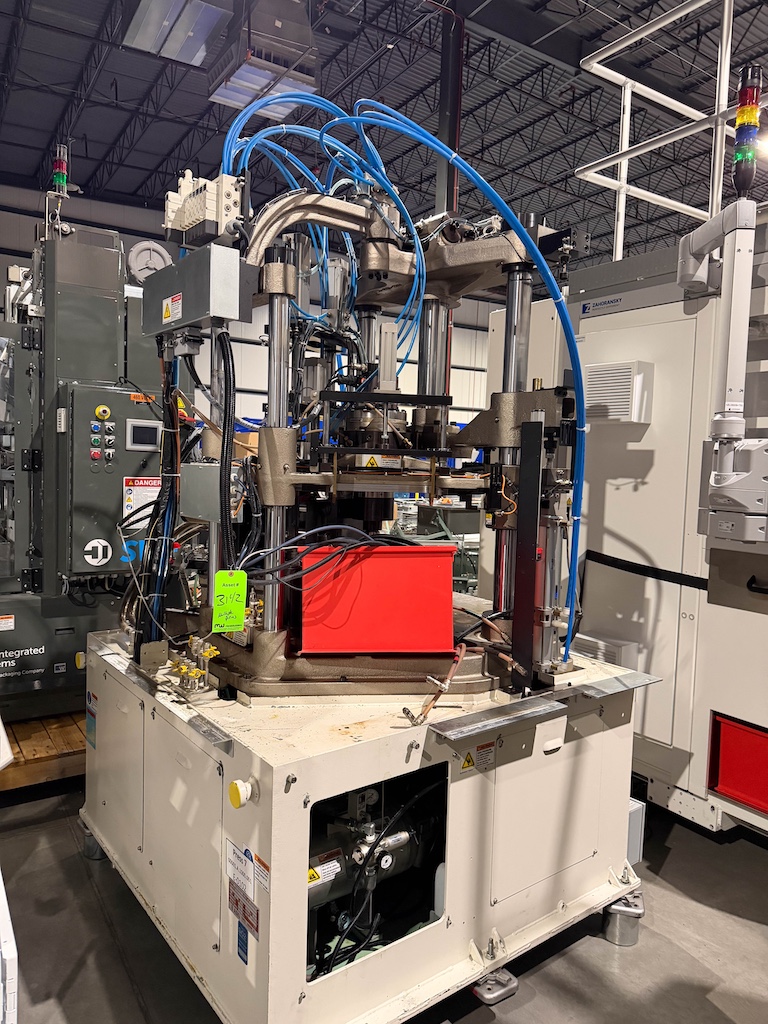

Tongda Blow Molding Machine

Item No. 5852

Year 2020

Tongda - HSII-12L/3

Item No. 5656

Year 2020

Aoki Blow Molding Machine, New in 2016

Item No. 5886

Year 2016

Aoki Blow Molding Machine, New in 2012

Item No. 5887

Year 2012

2007 Nissei ASB PF8-4B

Item No. 5859

Year 2007

Milacron - 5511

Item No. 5511

Year 2001

Sterling Accumulator Head Blow Molder

Item No. 5857

Year 1997

Bekum - BM-705D

Item No. 5454

Looking for Something Specific?

Most of our blow molding machinery inventory sells before we can list it online. If you need a specific brand, model, or specification, contact us directly—we have access to unlisted equipment and machines coming in from plant closures.

Looking to Sell Your Blow Molding Machinery?

Meadoworks is an active cash buyer of used blow molding machinery. Get a free valuation from our AMEA-certified appraisers.

About Used Blow Molding Machinery

Browse Meadoworks' inventory of used blow molding machines for sale, including extrusion blow molding (EBM), injection blow molding (IBM), and stretch blow molding (SBM) equipment. Whether you're looking for a blow molding machine, blow moulding machine, blow molder, or plastic blow molding equipment, we stock machines from industry leaders including Graham Engineering, Uniloy, Bekum, Kautex, Wilmington, Jomar, Nissei ASB, Aoki, and Sidel. Our plastic blow moulding machine inventory covers applications from small pharmaceutical bottles to large industrial drums and automotive fuel tanks. Find continuous extrusion blow molding, accumulator head, shuttle, reciprocating screw, and wheel-type blow moulder machines with single or multiple cavities. Each blow mold machine listing includes detailed specifications covering clamp tonnage, shot capacity, head configuration, and parison programming capabilities. Whether you're producing HDPE containers, PET bottles, or custom industrial parts, Meadoworks has blow molding machinery and plastic blow moulding machine solutions at every price point. Contact us for blow molding equipment sourcing.

Browse used blow molding machinery for sale from top manufacturers.

What to Consider When Buying Used Blow Molding Machines

Selecting a used blow molding machine starts with understanding which process best suits your application. Extrusion blow molding (EBM) is the most common for HDPE bottles, containers, and industrial parts — look for accumulator head machines for large parts or continuous extrusion for high-volume production of smaller containers. Injection blow molding (IBM) produces precision neck finishes for pharmaceutical and cosmetic bottles. Stretch blow molding (SBM or ISBM) creates PET bottles with biaxial orientation for carbonated beverages and water.

Key specifications to evaluate include clamp tonnage, mold dimensions, number of stations, parison head configuration (single or multiple cavities), and shot capacity. For EBM machines, check accumulator capacity, die head condition, parison programming capabilities, and downstream trim equipment. For SBM, evaluate preform handling, oven zone configuration, and blow pressure capabilities. Always inspect the hydraulic system, heating elements, and control system vintage.

Why Buy Used Blow Molding Machines From Meadoworks

Meadoworks brings over 50 years of plastics industry expertise to every blow molding equipment transaction. Our team has deep relationships with major blow molding operations across North America, giving us early access to equipment from plant closings, line consolidations, and capacity adjustments before machines hit the open market.

We carry blow molding equipment from all major manufacturers and can help you evaluate machines for your specific container requirements. Whether you're producing pharmaceutical bottles, industrial drums, or automotive fuel tanks, our technical knowledge ensures you get the right machine. We coordinate worldwide shipping with experienced rigging teams familiar with the special handling requirements of blow molding equipment. Contact us at 800-323-0307 for inventory, pricing, and equipment sourcing assistance.

Frequently Asked Questions

What types of blow molding machines does Meadoworks carry?

We stock extrusion blow molding (EBM), injection blow molding (IBM), and stretch blow molding (SBM) machines. Our inventory includes continuous extrusion, accumulator head, shuttle, and wheel-type machines from Graham, Uniloy, Bekum, Kautex, Wilmington, Jomar, and Sidel.

What's the difference between extrusion and injection blow molding?

Extrusion blow molding extrudes a parison that's captured in a mold and inflated—ideal for HDPE bottles and containers. Injection blow molding first injection molds a preform, then transfers it to a blow station—better for precision neck finishes and smaller pharmaceutical bottles.

Can Meadoworks help with blow mold tooling?

Yes, we occasionally have blow molds available with machines or separately. We can also connect you with tooling sources for new molds. Contact us with your container specifications and we'll help identify solutions.

Ready to find the right blow molding machinery? Call us at 800-323-0307 or submit a request through our equipment locator form.

Buying Guides & Resources

Helpful resources to guide your equipment purchase decisions.