Beamer - FB23

Item No. 5808

Year 2024

Beamer - FB23

Item No. 5807

Year 2024

Beamer - FB23

Item No. 5809

Year 2024

Beamer - FL23

Item No. 5811

Year 2024

Dener - Puma XL-30100

Item No. 5830

Year 2023

Dener - Puma XL-30100

Item No. 5829

Year 2023

Yangli - BL3015F-10

Item No. 5814

Year 2021

Yangli - BL3015F-10

Item No. 5815

Year 2021

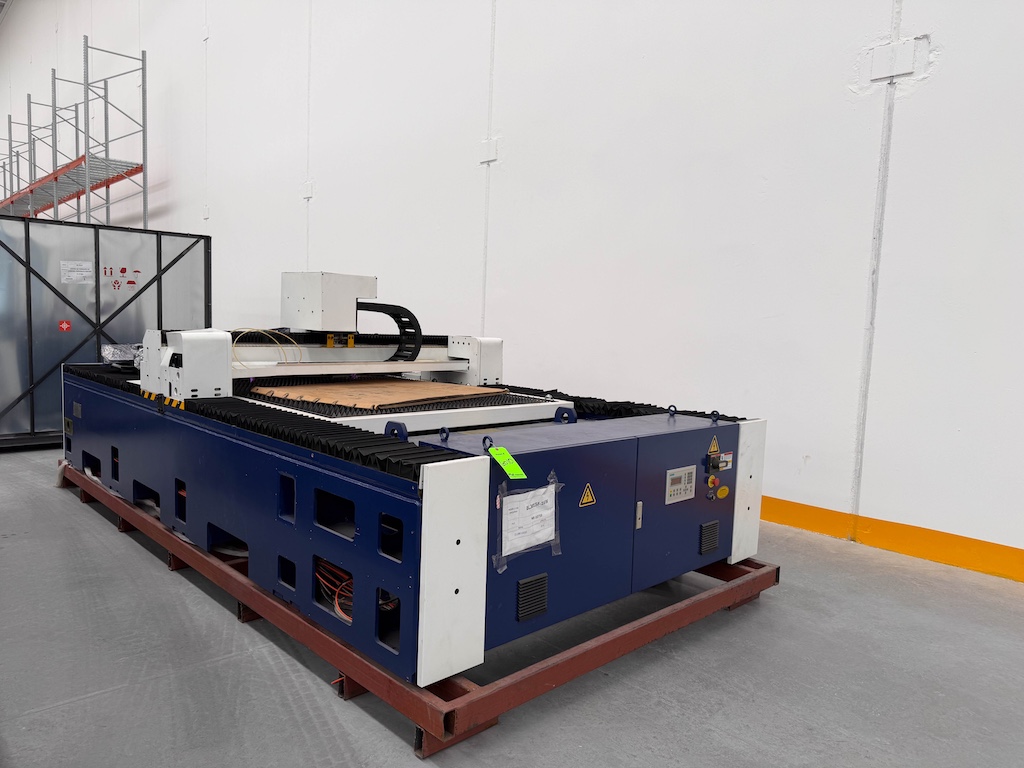

Yangli - GL4020F-20

Item No. 5816

Year 2021

Hornet - Mega Hornet 1000

Item No. 5832

Year 2019

Piranha - Pro2

Item No. 5707

Year 2000

Looking for Something Specific?

Most of our fabricating equipment inventory sells before we can list it online. If you need a specific brand, model, or specification, contact us directly—we have access to unlisted equipment and machines coming in from plant closures.

About Fabricating Equipment

Find quality used fabricating equipment for sale at Meadoworks, including press brakes, shears, laser cutters, plasma cutters, punch presses, roll forming equipment, ironworkers, and welding systems. Our inventory features machines from Amada, Trumpf, Bystronic, Cincinnati, Accurpress, LVD, Prima Power, Mazak, and other leading fabrication equipment manufacturers. We stock hydraulic press brakes, mechanical shears, fiber lasers, CO2 lasers, CNC turret punches, and automated fabrication cells. Each listing includes detailed specifications for tonnage, bed length, stroke, and control system capabilities. Whether you're cutting, bending, punching, or forming sheet metal and plate, Meadoworks offers fabrication solutions at every price point. Our team can help you evaluate machines for your specific material thickness, tolerance, and production volume requirements. We ship fabricating equipment worldwide with experienced rigging partners.

Browse used fabricating equipment for sale from top manufacturers.

Frequently Asked Questions

What fabricating equipment does Meadoworks carry?

We stock press brakes, shears, laser cutters, plasma cutters, punch presses, roll forming equipment, ironworkers, and welding systems from Amada, Trumpf, Bystronic, Cincinnati, Accurpress, LVD, Prima Power, Mazak, and other leading manufacturers.

What's the difference between fiber lasers and CO2 lasers?

Fiber lasers excel at cutting thin to medium gauge metals (especially reflective materials like aluminum and copper) with lower operating costs and minimal maintenance. CO2 lasers are still preferred for thick mild steel and non-metallic materials. Fiber lasers have largely become the standard for sheet metal fabrication.

How do I determine the tonnage needed for a press brake?

Press brake tonnage depends on material type, thickness, bend length, and die width. Wider V-dies require less tonnage but produce larger radii. Meadoworks can help you calculate tonnage requirements—contact us with your material specs and bend requirements.

Have more questions? Contact our team or call us at +1-847-640-8580.

Buying Guides & Resources

Helpful resources to guide your equipment purchase decisions.