Wittmann - Hot Oil Thermolator

Item No. 5845

Year 2024

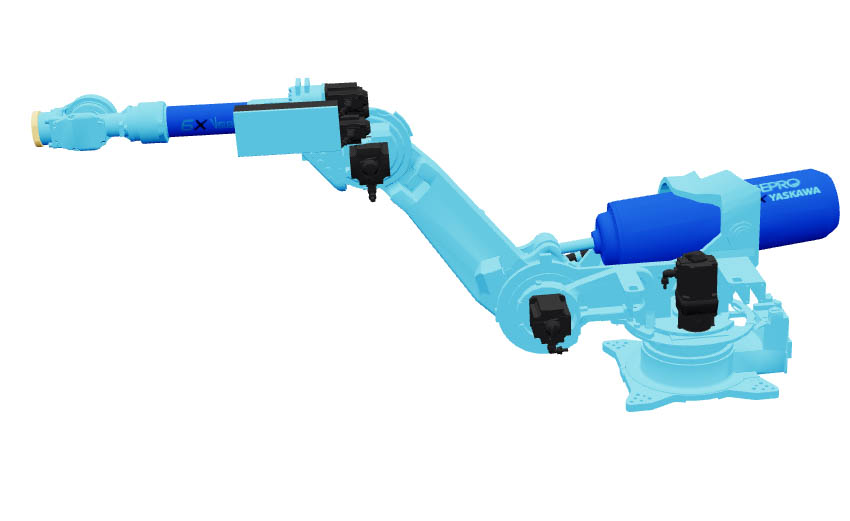

Sepro - 6X-205.2

Item No. 5618

Year 2024

Wittmann - Tempro Plus D200

Item No. 5844

Year 2023

Wittmann - Tempro Plus D200

Item No. 5841

Year 2023

Wittmann - Tempro Plus D200

Item No. 5842

Year 2023

Wittmann - Tempro Plus D200

Item No. 5843

Year 2023

Wittmann - Tempro Plus D200

Item No. 5840

Year 2023

Wittmann - Chiller

Item No. 5834

Year 2023

Wittmann - Gravimax G76

Item No. 5839

Year 2022

Wittmann - Material Loader

Item No. 5833

Year 2022

Wittmann - Flowcon Plus

Item No. 5846

Year 2021

Wittmann - Generation 3

Item No. 5836

Year 2021

Yushin - YCII-800S

Item No. 5728

Year 2019

Wittmann - Gravimax G34

Item No. 5838

Year 2018

Wittmann - SJM2A

Item No. 5835

Year 2018

Wemo - 3-5 Linear Picker

Item No. 5719

Year 2018

Wemo - 8-5 eDesign

Item No. 5720

Year 2018

Wemo - 3-5 Linear Picker

Item No. 5718

Year 2018

Wemo - 3-5 Linear Picker

Item No. 5716

Year 2018

Wemo - 3-5 Linear Picker

Item No. 5717

Year 2018

Elmet - TOP 5000 P

Item No. 5675

Year 2017

Wittmann - Gravimax G34

Item No. 5837

Year 2015

Hermann - PS Dialog

Item No. 5605

Year 2006

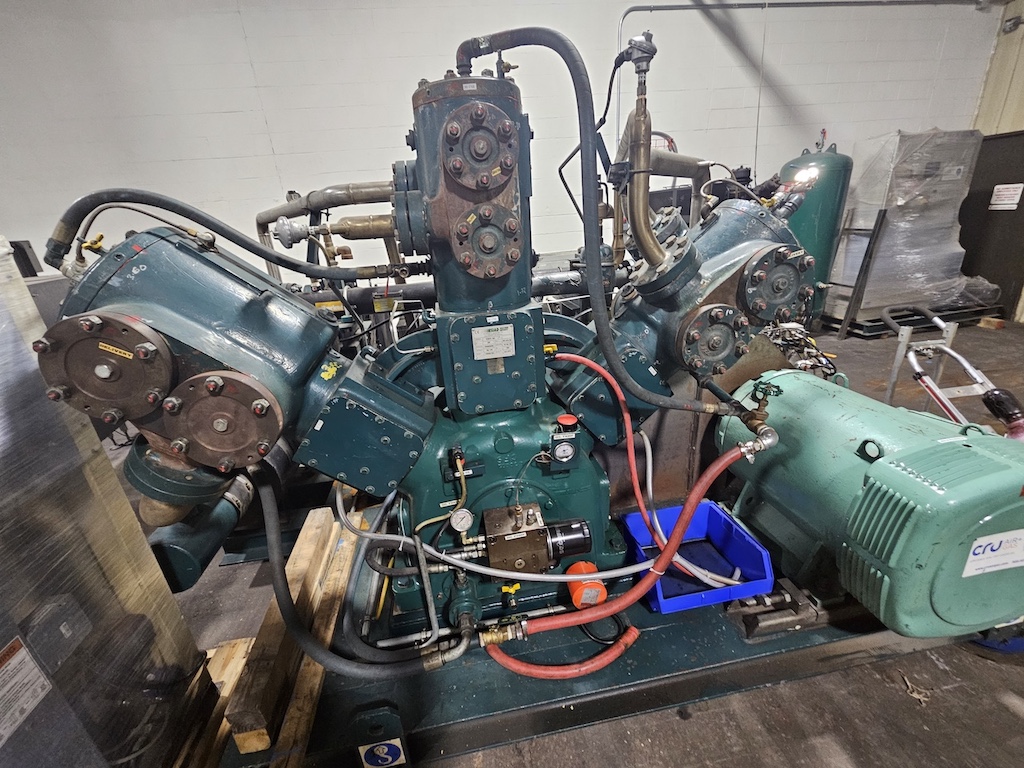

Siad - Tempo 950 - High Pressure

Item No. 5713

Year 2004

Thermal Care - LQ2W1504

Item No. 3705

Year 2004

15 Tons

Looking for Something Specific?

Most of our plastic auxiliary equipment inventory sells before we can list it online. If you need a specific brand, model, or specification, contact us directly—we have access to unlisted equipment and machines coming in from plant closures.

About Plastic Auxiliary Equipment

Browse Meadoworks' extensive inventory of used plastic auxiliary equipment essential for any molding or extrusion operation. Our selection includes material dryers (desiccant, hot air, vacuum), chillers and temperature controllers, granulators and grinders, material loaders and conveyors, blenders and feeders, mold temperature controllers, and hot runner systems. We stock auxiliary equipment from Novatec, Conair, Motan, Wittmann, Una-Dyn, Advantage, Mokon, Cumberland, Rapid, Foremost, Maguire, and other industry leaders. Proper auxiliary equipment is critical for part quality—material moisture affects surface finish and mechanical properties, while temperature control impacts cycle times and dimensional stability. Every listing includes detailed specifications and condition reports. Whether you're setting up a new processing cell or upgrading existing equipment, Meadoworks offers auxiliary solutions at every budget level. We ship worldwide and can help you spec equipment for your specific resin and throughput requirements.

Browse used plastic auxiliary equipment for sale from top manufacturers.

Frequently Asked Questions

What auxiliary equipment do I need for injection molding?

Essential auxiliary equipment includes a material dryer (especially for hygroscopic resins like nylon and PET), chiller or temperature controller for mold cooling, and a granulator for regrind. Additional equipment may include loaders, blenders, dehumidifiers, and robots depending on your application and automation level.

What brands of auxiliary equipment does Meadoworks carry?

We stock auxiliary equipment from Novatec, Conair, Motan, Wittmann, Una-Dyn, Advantage, Mokon, Sterling, ACS, Cumberland, Rapid, Foremost, Maguire, and other industry leaders covering drying, cooling, grinding, and material handling.

Why is material drying important for plastics processing?

Many plastics (nylon, PET, PC, ABS, PBT) absorb moisture from the air. Processing wet material causes splay, bubbles, reduced strength, and poor surface finish. Proper drying to manufacturer-specified moisture levels is critical for consistent part quality and process stability.

Have more questions? Contact our team or call us at +1-847-640-8580.

Buying Guides & Resources

Helpful resources to guide your equipment purchase decisions.