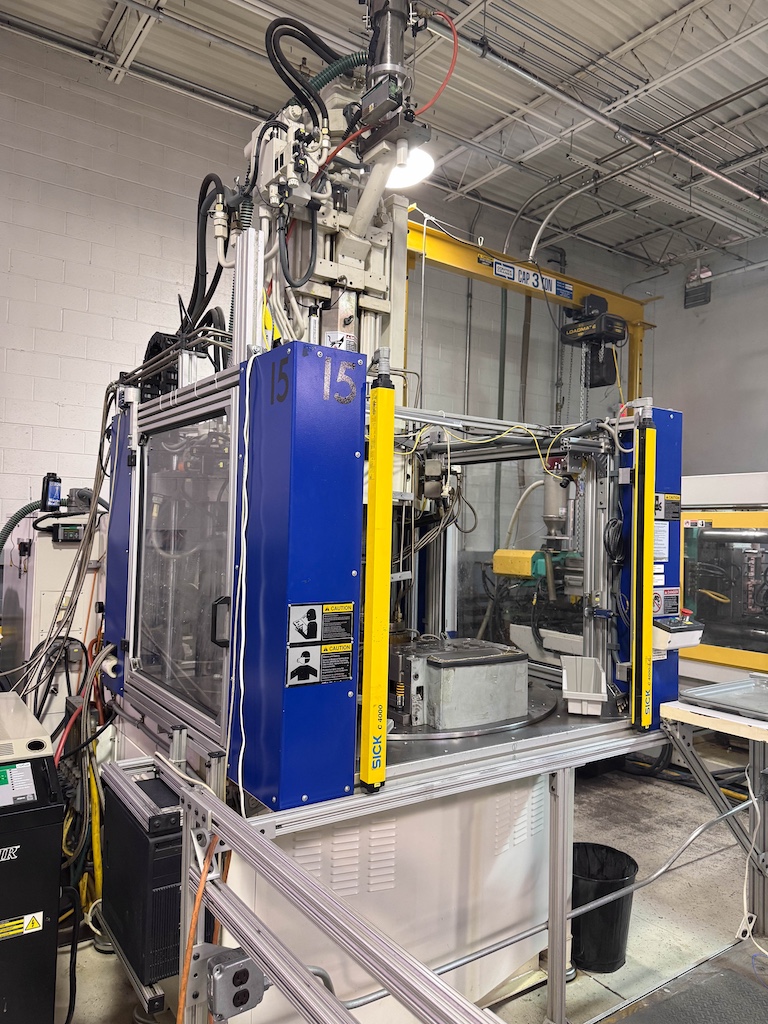

Used Vertical Plastic Injection Molding Machines for Sale

Used vertical injection molding machines for insert molding, over-molding, and multi-material applications. Shuttle table, rotary table, and single-station configurations.

Browse by Type:

Available Equipment(12 items)

2010 Battenfeld VM 270/750V R 1755

Item No. 5994

🇺🇸 USAYear 2010

2006 Battenfeld Vertical R 150/400V

Item No. 5993

🇺🇸 USAYear 2006

165 Tons

2005 Cincinnati Milacron Magna V30-S

Item No. 5856

🇺🇸 USAYear 2005

30 Tons

Arburg - 375 V 500- 170

Item No. 5658

🇺🇸 USAYear 2022

50 Tons

Multiplas - VC-SD-35T

Item No. 5651

🇺🇸 USA35 Tons

Niigata - MDVR85S - Vertical/Vertical

Item No. 5676

🇺🇸 USAYear 2023

Arburg - 1500 T 1600-350/60, 2-Shot Vertical/Vertical

Item No. 4875

🇺🇸 USAYear 2005

160 Tons

Autojectors - HCR-90

Item No. 3873

🇺🇸 USAYear 1998

90 Tons

Autojectors - HS-35-S

Item No. 4737

🇺🇸 USAYear 1992

35 Tons

Cincinnati Milacron - HC 70

Item No. 3872

🇺🇸 USAYear 2003

70 Tons

Battenfeld - BA 300V / 50H

Item No. 3410

🇺🇸 USAYear 1990

33 Tons

NEWBURY - V6-76RS - Shuttle

Item No. 2008

🇺🇸 USAYear 1992

75 Tons

About Used Vertical Injection Molding Machines

Vertical plastic injection molding machines (also known as vertical injection moulding machines) feature a vertical clamping unit with the injection unit positioned above or beside the mold. This configuration is ideal for insert molding, over-molding, and multi-material applications where components are loaded into the lower mold half. Vertical injection molding machines use gravity to hold inserts in place, making them the preferred choice for embedding metal components, connectors, and other materials into plastic parts.

Vertical injection machines are available in shuttle table, rotary table, and single-station configurations. Shuttle table machines allow an operator to load inserts on one mold half while the other is cycling, maximizing productivity. Rotary table vertical molding machines offer even higher throughput with multiple stations. Single-station vertical plastic molding machines are compact and cost-effective for lower-volume production.

Meadoworks stocks used vertical injection molding machines from Engel, Arburg, Nissei, Boy, Newbury, and other leading manufacturers. Whether you need a small vertical plastic moulding machine for connector insert molding or a large vertical injection machine for automotive over-molding, contact our team at 800-323-0307.

Common Applications

Frequently Asked Questions

What is a vertical injection molding machine used for?

Vertical injection molding machines (also called vertical injection moulding machines) are primarily used for insert molding — embedding metal pins, connectors, bearings, or other components into plastic parts. The vertical configuration uses gravity to hold inserts in place in the lower mold half while the upper clamp closes from above. They're also used for over-molding, multi-material molding, and applications requiring bottom-side access to the mold.

How much does a used vertical injection molding machine cost?

Used vertical plastic injection molding machine prices range from $10,000-$40,000 for small single-station machines (10-50 tons) to $50,000-$200,000+ for larger shuttle or rotary table machines (100-500 tons). Pricing depends on brand, tonnage, table configuration, and condition. Contact Meadoworks at 800-323-0307 for current pricing on specific machines.

What is the difference between vertical and horizontal injection molding machines?

The primary difference is the orientation of the clamp. Horizontal machines open/close along a horizontal axis and are the standard for most molding applications. Vertical machines open/close vertically and excel at insert molding because gravity holds components in the lower mold half. Vertical machines typically have a smaller footprint but may require more vertical clearance.

Need Help Finding the Right Equipment?

Contact our team with your specifications and we'll help you find the right machine.

Looking to Sell?

Meadoworks is an active cash buyer of used plastics equipment. Get a free valuation.

Get a Free Valuation